- Sun Mar 29, 2009 6:14 pm

#69571

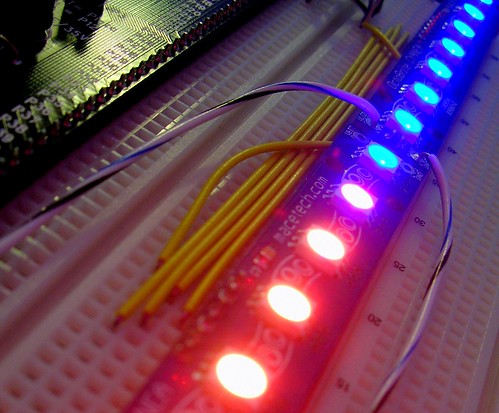

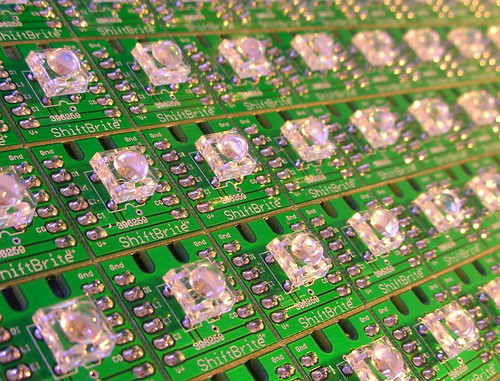

LEDs are through hole. I couldn't find SMT RGB LEDs cheaper than a $1 or so, and I didn't want to shell out $256 per tile of LEDs. I have yet to make the board, so I can put a solder mask on there if need be. It will also probably be a large board, 8 to 12 inches squared.

Anyone have a recommendation on an assembly company? It's a prototype so it doesn't need to be anything professional.

What about a solder pot? Is such a thing recommended?

Can I use a wave solderer with through hole?

Anyone have a recommendation on an assembly company? It's a prototype so it doesn't need to be anything professional.

What about a solder pot? Is such a thing recommended?

Can I use a wave solderer with through hole?