- Sat Jul 04, 2009 11:10 pm

#76345

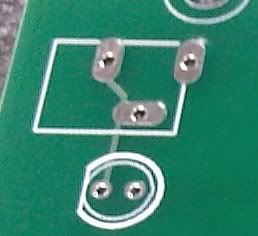

DC Barrel Power Jack

(http://www.sparkfun.com/commerce/produc ... cts_id=119)

This jack has three flat prongs but the Eagle library produces circular holes that are too small. Is there any way to make an elongated-through hole in Eagle to match the prongs?

Is there an actual problem with the Eagle library or am I doing something incorrectly? (I am still new at this.)

(http://www.sparkfun.com/commerce/produc ... cts_id=119)

This jack has three flat prongs but the Eagle library produces circular holes that are too small. Is there any way to make an elongated-through hole in Eagle to match the prongs?

Is there an actual problem with the Eagle library or am I doing something incorrectly? (I am still new at this.)