- Mon Mar 25, 2013 6:03 am

#157392

Hello,

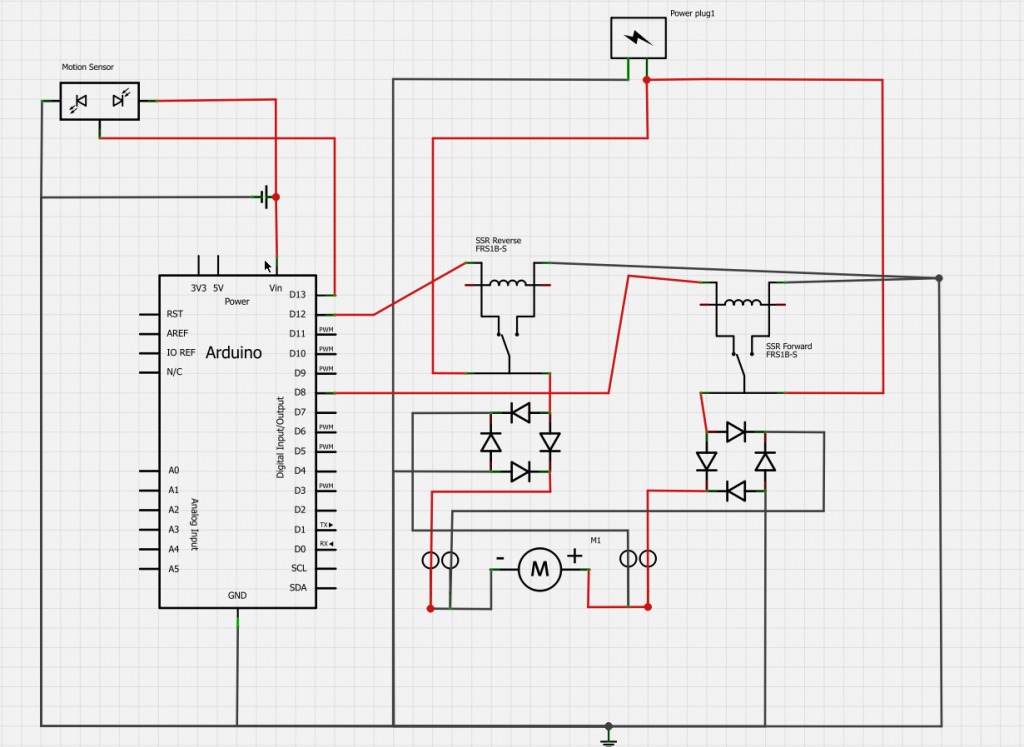

I am attempting a DIY project that will be requiring a small amount of sparky goodness and micro-controlling. The aim for this project is to be low cost, and because of this I am trying to use some existing equipment that I already have to work around. Without getting too involved with the gruesome details of the project, in a nutshell I am trying to control a low rpm high torque 115VDC motor, keyed by the nifty PIR motion sensor.

Here is the breakdown of my design challenges. (Keep in mind that I am doing this project for the challenge, and that I am very new to the micro controller sparkfun world)

1: I am trying to select the right micro controller, I have looked into the Arduino R3, the Wixel, and the Arduino mini. From what I gather, the Wixel has some very user friendly programmer apps that I can use that will make the programming less of a headache. However, I am intrigued by the coding aspect of the project and would love to sit down and write the code for an Arduino just to learn a tid bit about writing code. (I have very basic C++ training)

2: Given the 115VDC motor that I am using that is almost perfect for the application, I am struggling to find a way to integrate such a high voltage motor into my controller circuit. I have contemplated using the H-Bridge Driver - NJM2670E3 in order to drive the motor at around 55-60VDC, given that I am not worried too much about the speed of my motor. Any thoughts on a similar style, cheap driver, that will allow me to use the full 115V of my motor? If not, would the above mentioned H-Bridge driver be suitable to drive my motor forward and backward using one of the micro controllers from my selection?

3: Lastly, I am trying to use the PIR motion sensor to key the motor. Once the motion sensor is triggered, I want to program the controller to have a time delay and then power the motor. Any starting tips for how to set this up in Arduino code? Just some simple pseudo code logic is what I'm looking for here.

Any and all help will be greatly appreciated, I am already having a blast just planning this project out. Thanks!

I am attempting a DIY project that will be requiring a small amount of sparky goodness and micro-controlling. The aim for this project is to be low cost, and because of this I am trying to use some existing equipment that I already have to work around. Without getting too involved with the gruesome details of the project, in a nutshell I am trying to control a low rpm high torque 115VDC motor, keyed by the nifty PIR motion sensor.

Here is the breakdown of my design challenges. (Keep in mind that I am doing this project for the challenge, and that I am very new to the micro controller sparkfun world)

1: I am trying to select the right micro controller, I have looked into the Arduino R3, the Wixel, and the Arduino mini. From what I gather, the Wixel has some very user friendly programmer apps that I can use that will make the programming less of a headache. However, I am intrigued by the coding aspect of the project and would love to sit down and write the code for an Arduino just to learn a tid bit about writing code. (I have very basic C++ training)

2: Given the 115VDC motor that I am using that is almost perfect for the application, I am struggling to find a way to integrate such a high voltage motor into my controller circuit. I have contemplated using the H-Bridge Driver - NJM2670E3 in order to drive the motor at around 55-60VDC, given that I am not worried too much about the speed of my motor. Any thoughts on a similar style, cheap driver, that will allow me to use the full 115V of my motor? If not, would the above mentioned H-Bridge driver be suitable to drive my motor forward and backward using one of the micro controllers from my selection?

3: Lastly, I am trying to use the PIR motion sensor to key the motor. Once the motion sensor is triggered, I want to program the controller to have a time delay and then power the motor. Any starting tips for how to set this up in Arduino code? Just some simple pseudo code logic is what I'm looking for here.

Any and all help will be greatly appreciated, I am already having a blast just planning this project out. Thanks!